ASPHALT PLUS CASE STUDY:

STATE ROUTE 22, HOPKINTON, GA

I-75 is a major artery in GA, connecting Atlanta to southern Georgia and Florida. The roadway is located in a subtropical climate where stripping and rutting are significant issues for asphalt road construction. The region is exposed to extended periods of higher temperatures, humidity and rainfall.

In preparation for an eventual state specification of the dry mix process, GA DOT contracted for twenty lane miles of 1.5” dry mix rubberized asphalt overlay on I-75 south of Valdosta, GA in 2010.

The mix design utilized 10 lbs of ASTM minus 30 crumb rubber and a 64,-22 PG rated binder. After rubber addition, the PG rating improved to an average in excess of 80, -22. The road surface was installed without incident, and both plant and road production crews noted that the process was straightforward, forgiving and simple to implement.

During placement, the CRM asphalt did not exhibit any of the stickiness typically found with other rubber addition processes. The hot mix product was placed and compacted with ease. Rutting and compaction evaluations of the plant production exhibited excellent results.

After four years of service, the surface is free of any material cracking and free of potholes. No evidence of unusual substrate or surface cracking has been noted to date. Product performance led to a state specification of dry mix asphalt in GA and multiple interstate projects in the following years.

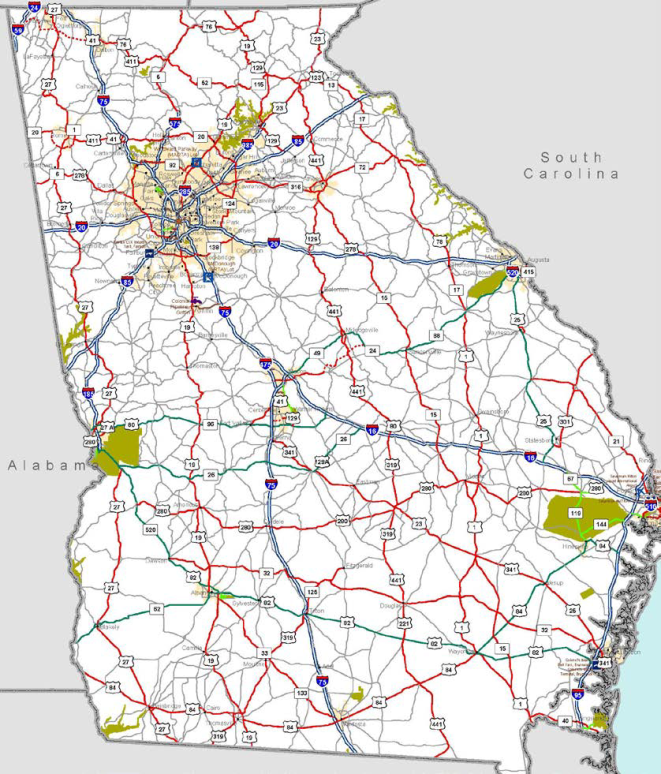

GA Interstate and Highway Projects, 2006 – 2013