Over the past decade, researchers in the U.S. have tried to develop an approach that will allow the introduction of dry process rubberized asphalt pavement in a way that is both cost-effective and free of the engineering challenges that have limited the use of crumb rubber modifiers (CRM) in the past.

CRM has proven to last longer than regular asphalt, provide a quieter pavement, better traction, lower maintenance and a great return on investment, Red Clark, president of Asphalt Plus LLC told attendees at the Clemson University Global Tire Conference in April.

“Today, the customer is the key to getting recycled rubber into asphalt” Clark said. The rubber recycling industry needs to listen to the customers.

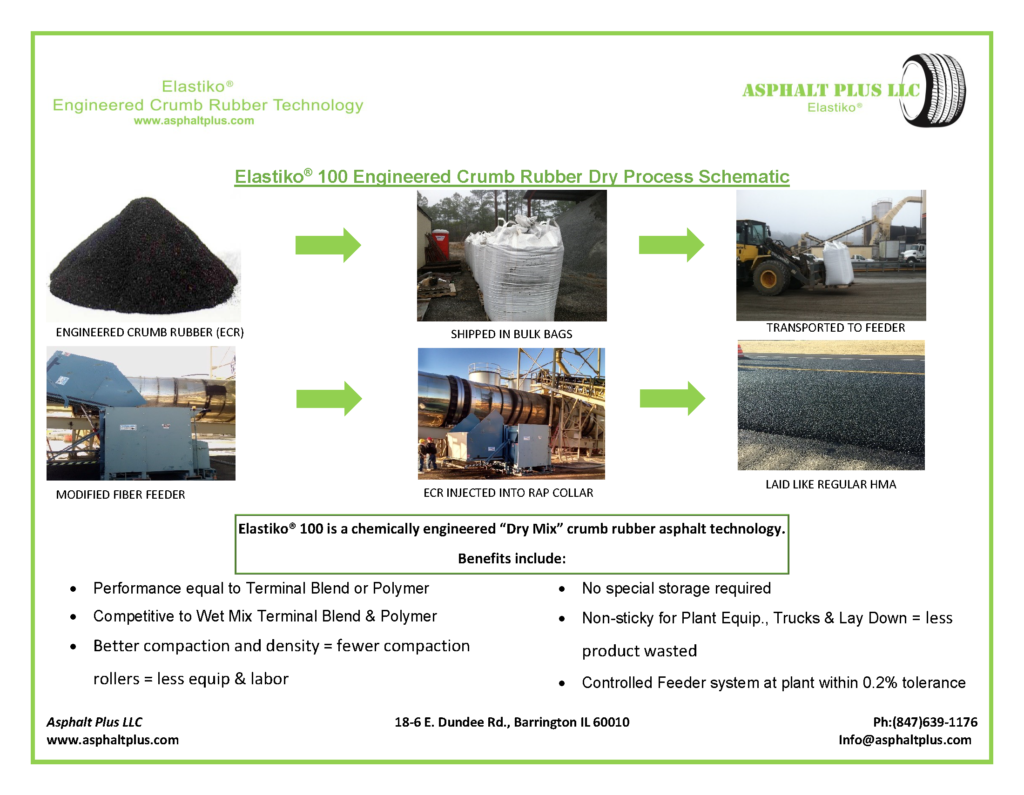

“Chemically engineered crumb rubber introduced like an aggregate into asphalt plants during mix production through a dry process meets those customer needs.”

Click links below to WATCH ASPHALT PLUS VIDEOS ON Engineered Crumb Rubber Technology!

The Dry Process Rubberized Asphalt helps with:

- Rutting resistance

- Cracking resistance

- Long road life cycle

- Skid resistance

- Durability in roads

- Reduces sound

- Serves as a way to recycle tires

- Reduces cost

- Less road maintenance

Asphalt Plus LLC is a specialty chemical and equipment manufacturing company headquartered near Chicago, IL. We produce an engineered crumb rubber additive for asphalt application. Asphalt Plus engineered rubber has endured a wide range of harsh climate & road use conditions. In spite of those tough situations, Asphalt Plus has performed impeccably well with nearly 3 million tons of placed Dry Process Rubberized Asphalt. We have assisted the auto manufacturing industry, the Department of Defense, Energy and Interior in cost-effectively reducing both their operating costs and their environmental footprint in a wide range of activities. Visit our site for more information.