ELASTIKO® RUBBERIZED ASPHALT INFORMATION:

GEOGRAPHIC PROJECT APPLICATIONS

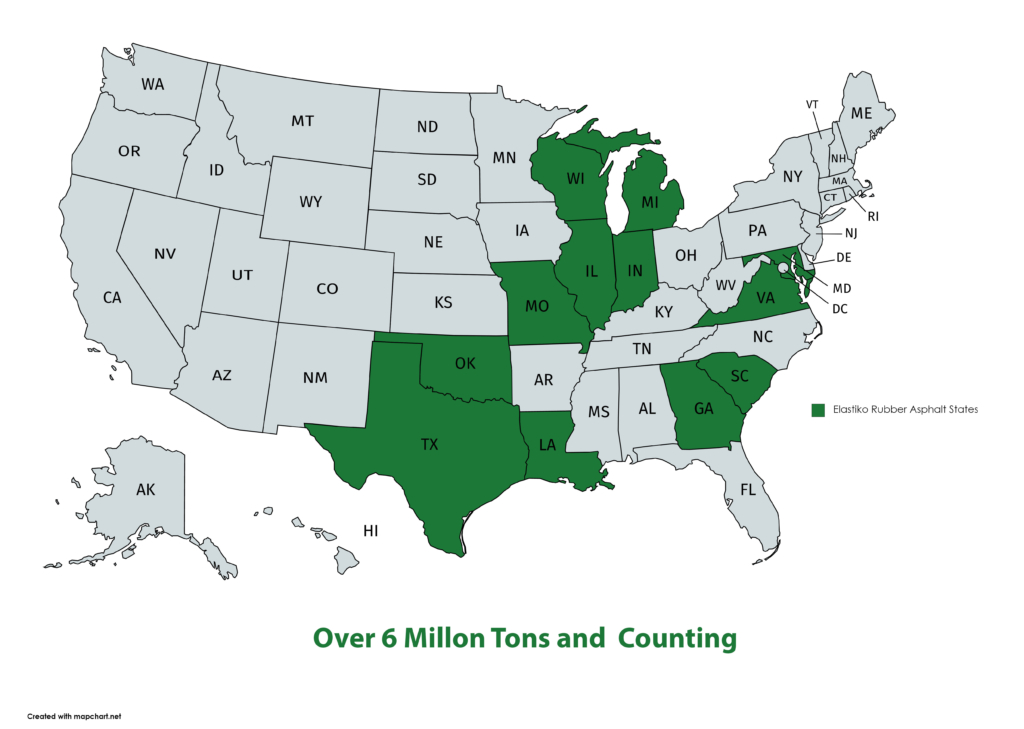

Below is a series of rubberized asphalt information using Elastiko™, a rapidly growing alternative to polymer modification. The product has been:

• Successfully used in multiple states across a wide array of climates.

• Applied in a wide range of asphalt mix designs.

• Used on full depth replacement, overlay and thinlay projects.

• Used on light, medium and heavy traffic roads for more than a decade.

• Thoroughly field-tested with multiple millions of tons in service.

The product is substantially less expensive than other forms of asphalt modification.

SUPERIOR RUTTING AND CRACKING RESISTANCE

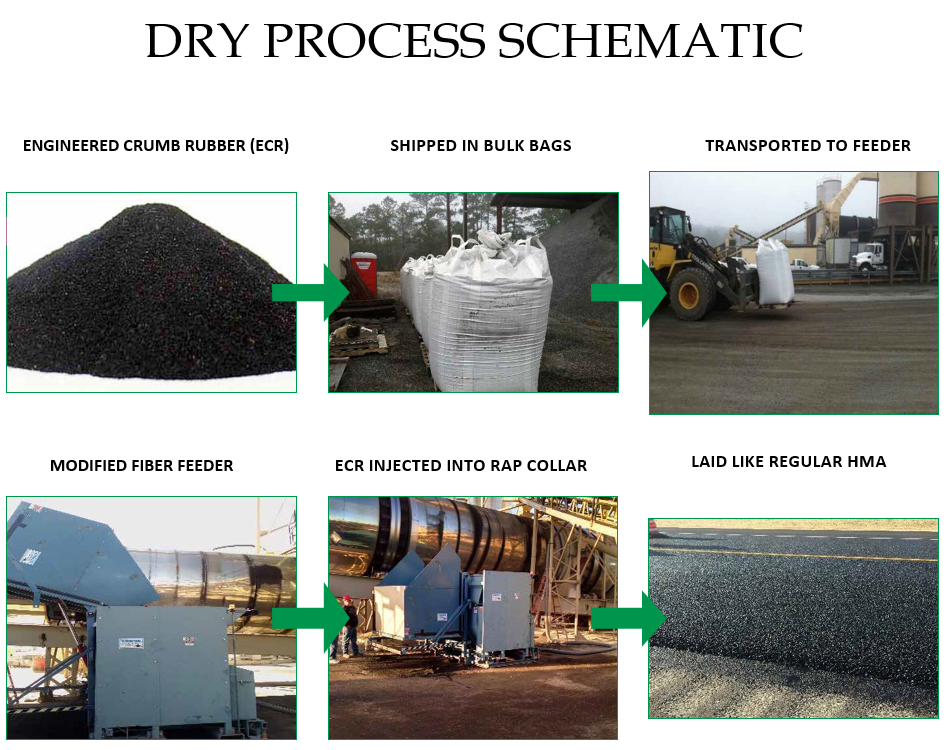

Elastiko® ECR is a chemically engineered “Dry Mix”

crumb rubber asphalt technology.

- Elastiko ECR is a chemically engineered recycled tire rubber product

- ISO-compliant ECR production: same product every order

- Easy delivery in bulk bags, no special storage

- Easy loading, feeding using a fiber machine

- Easy laydown and compaction, low/no waste

- Rubber blown into drum plants through RAP collar, belt-fed to batch plants

- No mix stickiness, easy to produce, load and unload

- Highly accurate feed rates tied to plant speed

SUPERIOR RUTTING AND CRACKING RESISTANCE

ECR BENEFITS

There are many benefits that afford to asphalt plants when they use ECR instead of polymer as a means of modification. Polymer modified asphalt tends to be sticky and hard to process through a plant’s system. As a result, production rates can be much less than if using ECR to modify your mix. Also, there tends to be no build up in conveyors, silos or other plant equipment when using ECR.

The use of ECR substantially reduces your cost when compared to polymer modification cost.

AGENCIES & ROAD OWNERS

People who manage roads, especially publicly funded ones, are having to do more with less given their budget restraints. That’s where rubberized asphalt information comes to the rescue. Everyone knows that ECR modified asphalt is less expensive to produce than polymer modified mixes. This reduced expense is passed along to road managers through lower bids, thus allowing limited resources to be spread out even further. So, not only do road owners get better roads, but they get better roads at a better price. Road owners realize: lower bid costs and better roads.

ENVIRONMENT

For every one lane mile of Elastiko modified asphalt laid, approximately 800 tires will be kept out of our limited landfills. Society realizes: better use of natural resources and less waste going to landfills.

SUPERIOR RUTTING AND CRACKING RESISTANCE

Rubberized Asphalt Information video